FULL AUTOMATED L-SEAL + SHRINK WRAPPING MACHINE

Italian historical and experienced L-Seal and Shrink Wrapping technology is condensed into the system FP6000CS + T-450, which is the professional and superior solutions for various packing processes such as foods, tools, printed stocks, stationeries, pharmaceutical and more. Fully automated from fed in to fed out items with higher outputs as well as the possibility of using Polyethylene film, besides the traditional shrink films and processing up to 3,600pph fastest. On-line connecting with T-450 Tunnel and also selectable Tunnels from SmiPack wide ranges fits to the application required. Max. packing size is up to 640mm(W) x 510mm(D) x 200mm(H) and system is well operated by safety devices and controls.

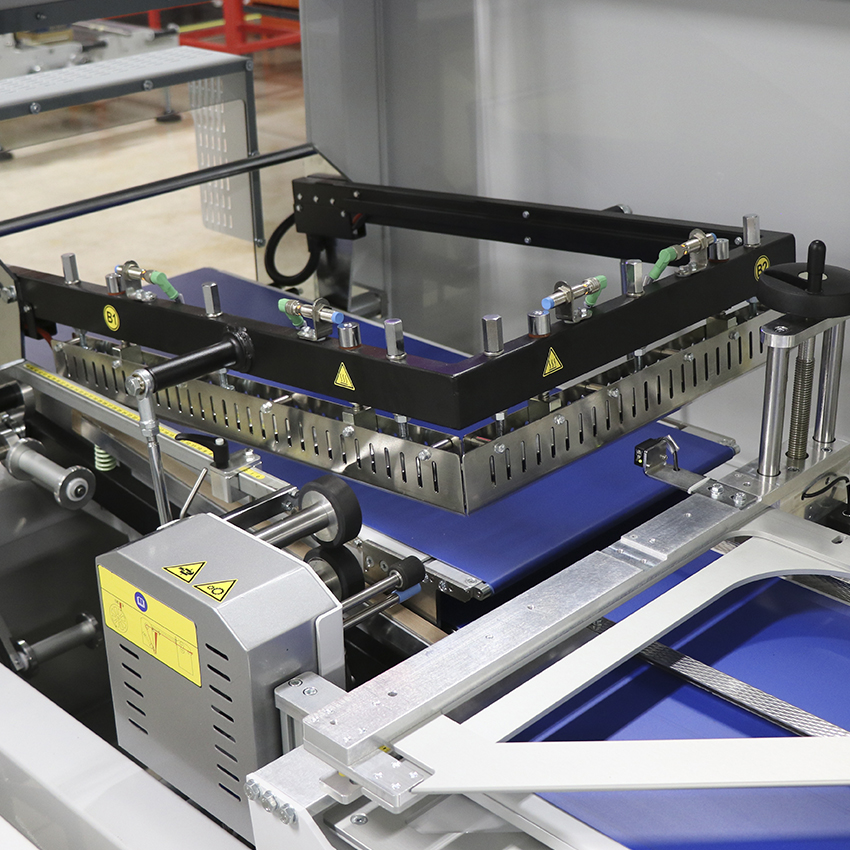

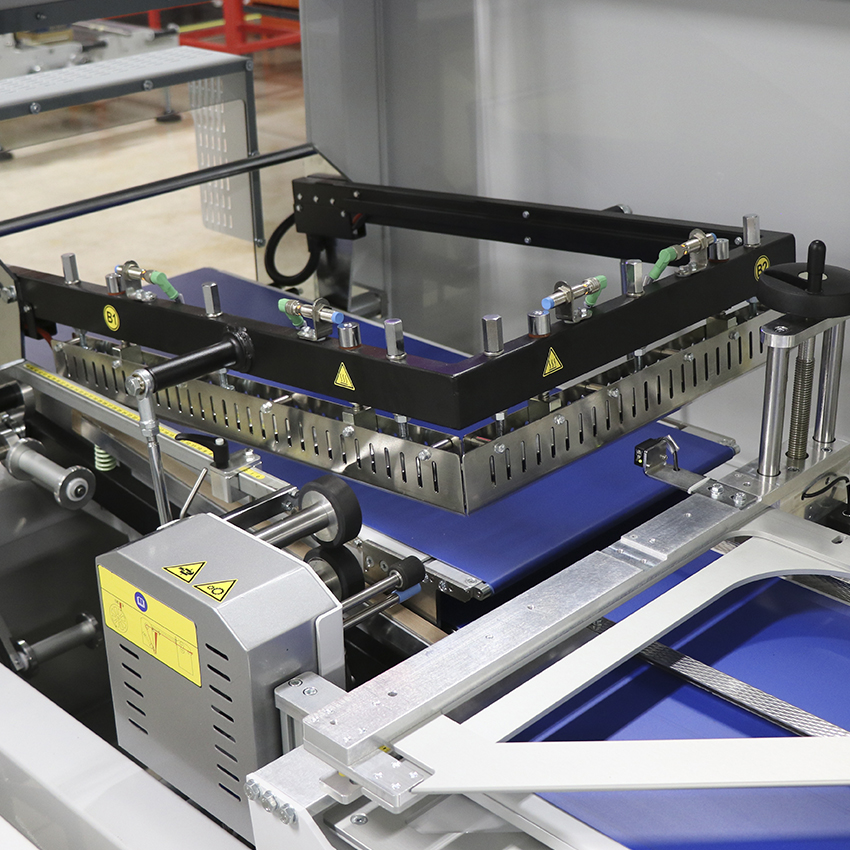

FULL ELECTRIC L-SEALING

L-sealing and shrink wrapping processes are fully automated with  + T-450 system and available continuing works with fed-in/out conveyer systems.(Option)

+ T-450 system and available continuing works with fed-in/out conveyer systems.(Option)

PTFE-COATED SEALING BLADE

PTFE-COATED SEALING BLADE

Sealing blade is coated by PTFE (Polytetrafluoroethylene) means Teflon coated sealing blade, which is enable for high durability and long time use.

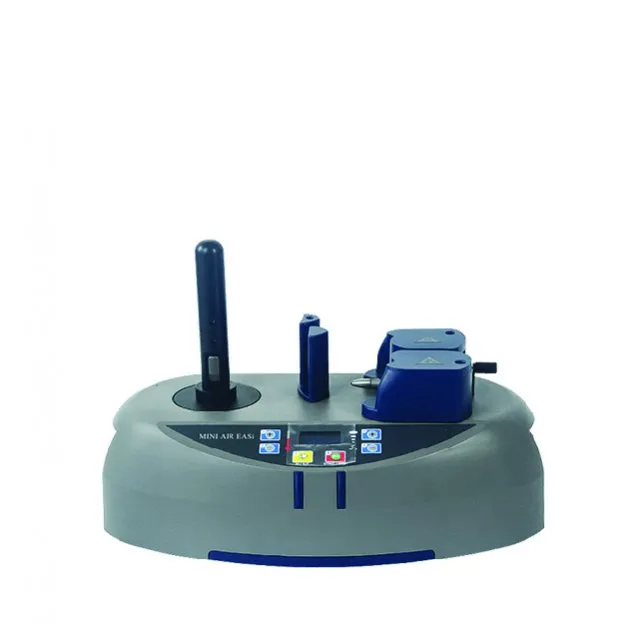

FLXMOD® CONTROL SYSTEM

FLXMOD® CONTROL SYSTEM

4,3" graphic LCD control panel with PLC and Modular power section made up by inverter for all motor and IN/OUT (inlet/outlet) digital and analog control modules

MOTALIZATION

FC-6000CS is fully motorized sealing bar controlled by inverter & encoder, conveyer closing system controlled by inverter and center seal system, which helps operator for setting jobs.

FP6000CS + T-450 System is the recommend solution for automating packing production line to increase productivity, high security and reduce human errors on line.

+ T-450 system and available continuing works with fed-in/out conveyer systems.(Option)

+ T-450 system and available continuing works with fed-in/out conveyer systems.(Option) PTFE-COATED SEALING BLADE

PTFE-COATED SEALING BLADE FLXMOD

FLXMOD