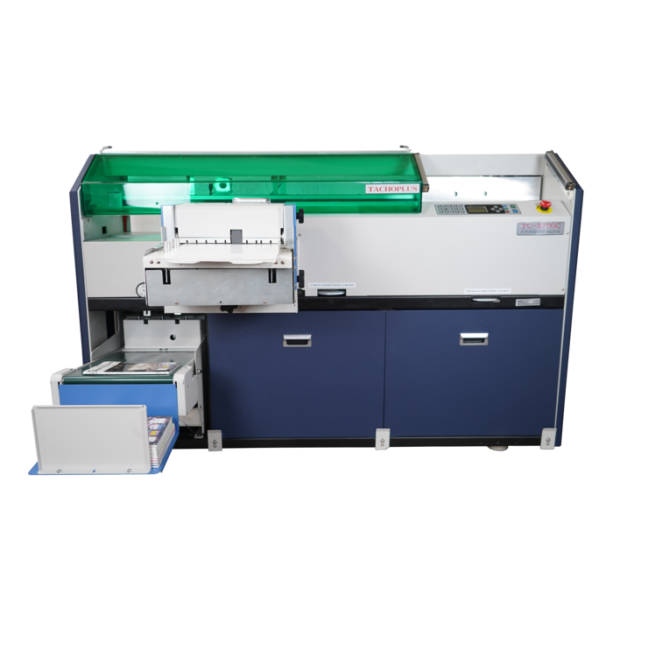

The redesigned die cutter,

ideal for short-run digital print finishing.

Customers want printed materials faster, personalized, and in the quantity they need, whether it's for unique shaped cards or boxes. The Die Cutting machine UCHIDA AeroDieCut gives printers and marketing service providers a new way to do this. It is easier than traditional large format die cutters and more productive than cutting plotters and laser cutters. The Die Cutting machine UCHIDA AeroDieCut can process complex cuts, creases, and perforations on printed materials in a single pass.

Feed Unit

The patented “Tri-suction feeder” ensures consistent paper feeding. The feeding unit equips an ultra-sonic sensor for double feed detection, and a cut-mark sensor to compensate image shift.

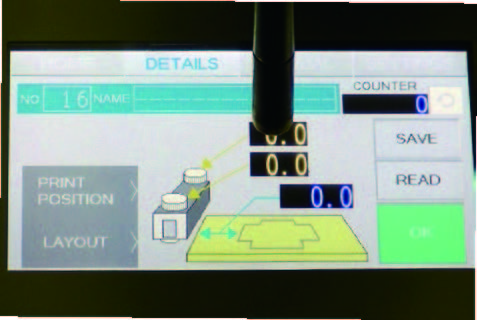

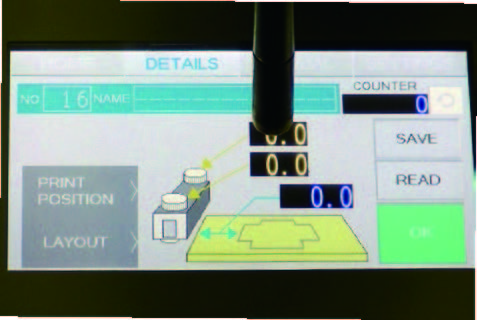

Easy touch screen operation

The 4” colored touch screen makes job settings and operation easy. 100 Job memories can be stored in the machine.

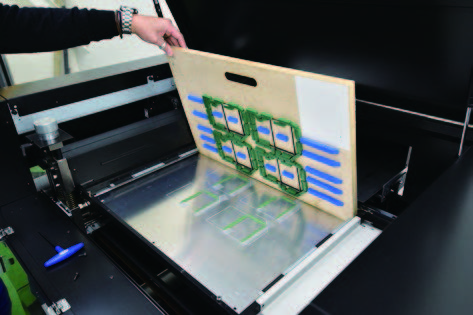

Main Unit (Press unit)

The main press unit uses patented “moving press rollers” mechanism to press the paper. This makes the die cutting process much quieter and power efficient than conventional die cutters.

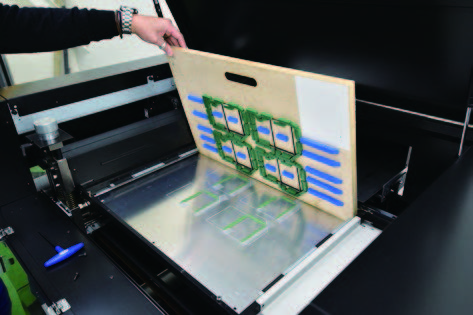

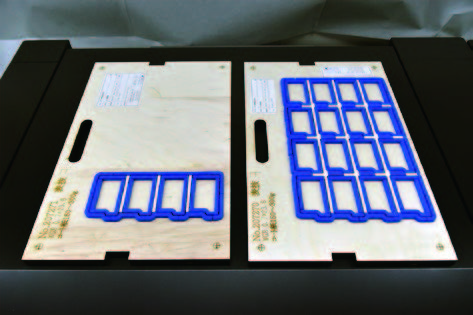

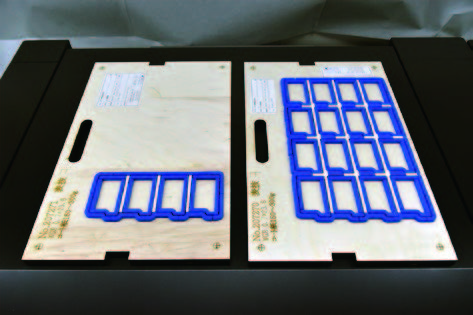

Multiple-up applications

The Die Cutting machine UCHIDA AeroDieCut features step & repeat function to finish multiple-up applications, which helps saving the cost of dies.

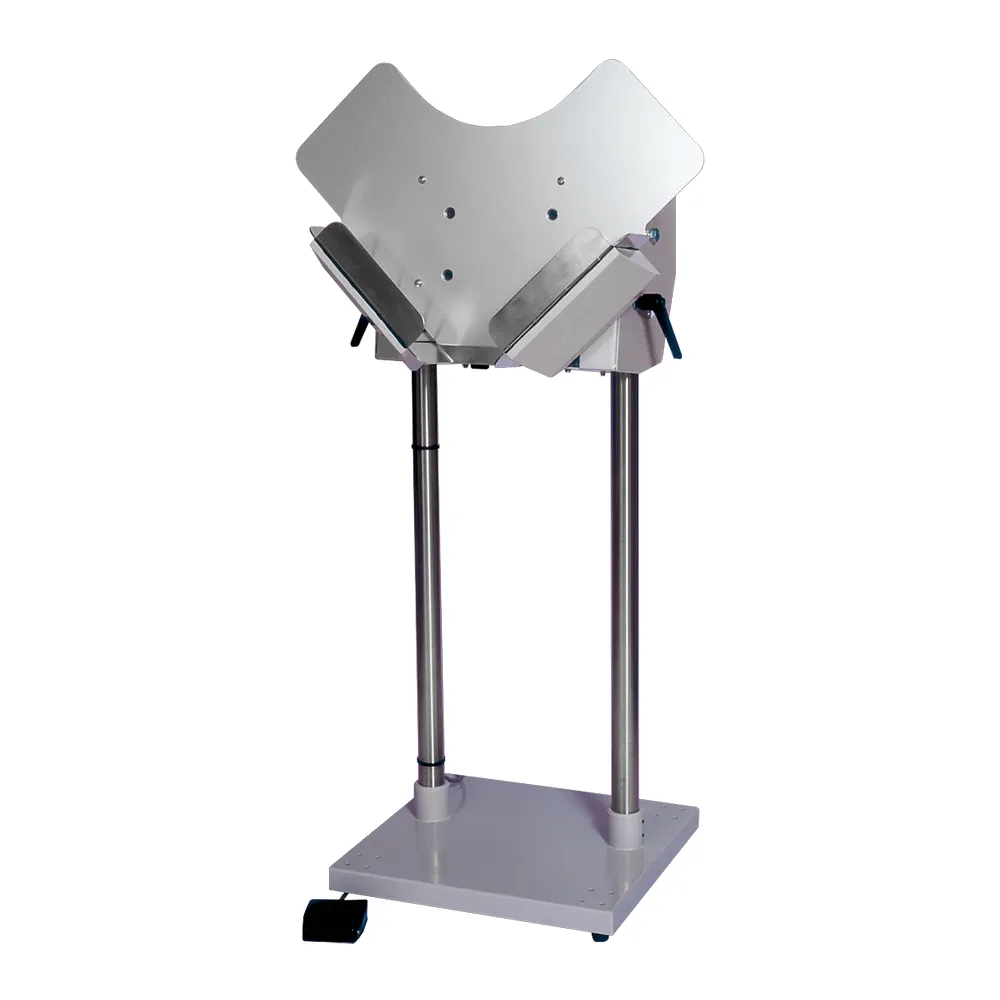

Optional separator & conveyor delivery

The optional separator deflects wastes into a waste bin as the die-cut paper is delivered. (Depending on layout).The optional conveyor delivery table makes collecting process more efficient.

Various applications

The Die Cutting machine UCHIDA AeroDieCut can cut, crease, and perforate on a print in a signle pass. It turns your prints into a variety of applications, such as cards, seing tags, boxes, envelops, shelf talkers,

The Die Cutting machine UCHIDA AeroDieCut can turn your printed materials into a variety of applications such as cards, boxes, swing tags, shelf talkers, etc. The Die Cutting machine UCHIDA AeroDieCut will help you turn your creativity into reality and help your business grow.